energy consumption calculation

Criteria

considers the following criteria for the energy consumption calculation:

| Cost of a kWh | The price for 1 kWh of electricity (euro) needs to be entered |

| Consider AC | Build-up heat in paper output systems causes increased electricity costs for air conditioning |

| Working days | The amount of working days per week needs to be entered. In order to calculate the total energy consumption, the power consumption per working day is being calculated and multiplied by the amount of working days per week. |

| Switching times in minutes (time in minutes from end of the print job till the device switches to low-power or sleep mode.) | Define the switching time for current and future state. That allows to optimize energy consumption by reconfiguring the activation times. |

| Average pages per job | Define the average pages per print job to calculate the amount of print jobs per day (based on the page volume).

E. g. an average of 5 pages per print job and a monthly volume of 1960 pages per month (or 98 pages per day) results in: 98 / 5 = 19.6 print jobs per day. (Note: the amount of print jobs per day must be more than 9 and less than 32.) |

| [RESULT] Number of print jobs per day (As a result of average job size in the monthly volumes) | You can decide whether the amount of print jobs per day is being calculated by using a formula (Source: TEC Measurement Procedure) or using fixed values for average print job size in current and future situations. If you provide the number of pages per job then no predefined formula will be used. |

| [RESULT] Number of print jobs per day using formula (As a result of average job size in the monthly volumes) |

Sample device: 14 pages per minute: Calculation of volume by ppm: 0.50 x 14² = 98 pages per day (Source: see Table 5 of TEC Measurement Procedure) |

| Use TEC only | Activating this option will calculate the direct energy consumption by TEC values only. All other energy consumption parameters (e.g. electricity price, print job size, power consumption etc.) get ignored in the calculation. TEC values only / none TEC values Example: TEC = 4.56 kWh / week kWh per month = 4.56 * 4 = 18.24 |

| Separate Energy form TCO | Activating this option will seperate the energy costs from the costs per device and shows them independentely. |

Asset energy consumption

Each asset in the database has individual energy values. In case that an asset lacks one or more of these values, calculates an average value of the missing value(s) (based on the value(s) of similar assets). So it’s possible to calculate an individual energy value for each asset.

In case the calculated average value is not meeting the expectation, it’s also possible to enter own energy values in the Energy section for each asset.

Explanation of the energy section fields

Calculation of energy consumption

The Energy Star® specification “Typical Electricity Consumption (TEC)” test procedure was taken as a basis for the new calculation concept.

To calculate the electricity consumption we first need to prepare the base data. The data contains some fixed integrated factors, values and some parameters from the project data which the user can influence. The base data includes the following:

- Use TEC values only (Yes/No)

- Electricity price (price per kWh)

- Consider Air Condition

- Working days per week (number of days)

- current and future switching times (4 x value in min.)

- Print jobs per day / formula (Yes/No)

- Number of pages in a print job for current and future (digit)

- How long is asset in use daily? (fixed value: 10 hours)

- Breakdown of operating time into morning and afternoon (5 hours each)

- Remaining time per working day for fax operation (14 hours)

- Remaining time for weekends for fax operation (depends on the number of working days)

- Number of print jobs per day (depends on 6 and 7)

- Number of weeks in the month (Fixed value: 4 weeks)

- How many minutes does the device have to wait before it can calculate the electricity consumption for the next print job on the basis of the initialisation phase (Fixed value: 10 minutes. (alternatively: Activation time Standby => Sleep: 5 minutes))

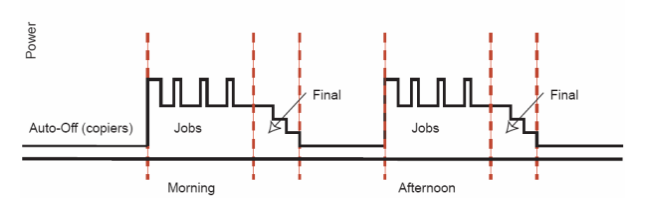

Fig 1: Breakdown of a working day into segments / clusters (source: TEC specification)

The 10-hour day is broken down into two main 5 hours segments (morning and afternoon). Each of these segments has a period with print jobs which are completed at 15 minutes intervals. After the final page of the last print job has been completed the final period starts to switch the device to standby and low power mode and finally sleep mode.

To determine the total electricity consumption, the first step is to calculate it for one segment (morning or afternoon). The print job size (no. of pages) and number of print jobs for one segment is determined using the mean volume and basis data.

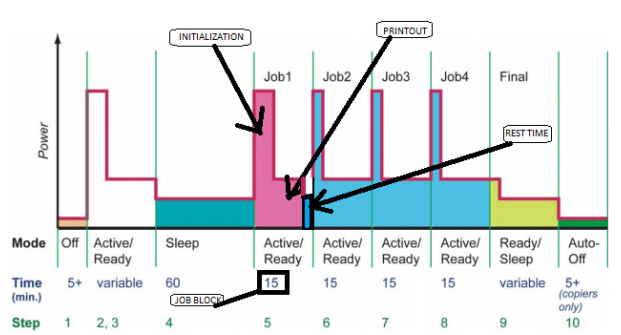

Fig 2: Breakdown of a single segment (Source: TEC Specification)

To determine the electricity consumption for the first print job, one job block is divided up into initialisation and print phase. The electricity consumption during initialisation is calculated using the initialisation time (specified per device: [Init] or [off]) and multiplied by the maximum consumption (or the power consumption during warm-up if applicable). The duration of the actual print-out is calculated from the speed and the number of pages in a print job, as well as the time taken to print first page.

The remaining time within a print job (15 minute block, Fig. 2) is calculated with the power consumption data from standby mode. If the activation times (from the project data) are shorter than 15 minutes, low power - and in some cases even sleep mode – is considered in the print job segment calculation. So all of the states are considered in this calculation. If the activation time is longer than 15 minutes, only standby (Ready) is put into the calculation for the remaining time.

The calculation of the second and subsequent print jobs is the same except of the initialisation phase. Depending on the last state after the last print job, the corresponding recovery time (i.e. from LP, Sleep or Stand-By) is considered in the calculation.

Note: In addition to power consumption data, the activation times are essential for the calculation. Changing the activation times can reduce or increase the electricity consumption by almost a factor of 1.5. There are circumstances which can lead to increased electricity consumption for very short activation times (e.g. less than 5 minutes in sleep mode). Due to a device takes some time to heat back up after an extended period in sleep mode print jobs might be treated like first rather than subsequent print jobs. Especially the time needed to heat up varies between all devices. These values are not specified and have to be calculated using a fixed value assumption (base values N).

Once the electricity consumption for all print jobs in one segment (morning) has been calculated, this value is multiplied by 2 (afternoon).The resulting value is the electricity consumption for the entire print jobs on one working day.

The next step is to determine electricity consumption in the final phase. This is done using the activation times and the power consumption data for stand-by, low power and sleep mode. Two factors are considered: what mode the last print job was completed in and how long this mode had been active. Finally – similar to print job calculation – the electricity consumption is determined by multiplying the operating state times and wattage values.

This is the procedure used to determine electricity consumption on one day. To work out the electricity consumption for a month, the electricity consumption for one working day is multiplied by the number of working days a week and then by 4 (weeks in the month).

TEC Only

If you would like to use the TEC figures instead of the integrated energy consumption calculation, just activate the TEC option in the project settings.